What is CNC turning and where is it used?

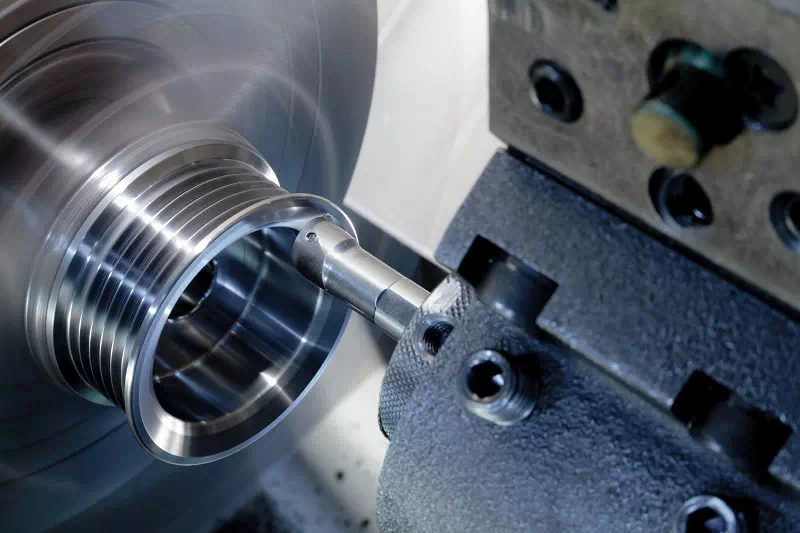

Turning is a type of chip processing, i.e. machining, which involves removing excess material with cutting tools. Turning is used to process external and internal rotating surfaces. CNC is a computer control of devices. CNC turning is therefore machining using modern numerically controlled machines using a computer. What else is worth knowing about CNC turning and its application?

Precise CNC turning based on computer design

Modern turning machine tools can be safely called CNC lathe centers, because they are extensive machines. Thanks to them, we make very precise elements created on the basis of computer projects. The workpiece is set in rotation (hence the name of turning), while the cutting tools are set in the right position using a computer. Their position changes, of course, during processing, to finally give the object the given shape. The CNC lathe operator introduces the project into the machine tool's computer, which, by reading it, regulates the work of tools in space and time. This ensures high productivity and high accuracy.

The use of CNC turning

Modern CNC turning, like CNC milling, allows machining of elements extremely precisely. We mention milling not by accident, because we want to explain how it is actually different from turning. We use milling to process flat and shaped surfaces, it is to make grooves, threads, gears, etc. Turning, on the other hand, is used to shape the surfaces of rotating solids - shafts, cones, balls. When it comes to materials subjected to various CNC machining techniques, it is primarily steels, but also aluminum, metal alloys and plastics. Steel comes first here due to demand: steel elements are parts of various types of machines, devices, equipment or various types of installations.