How are precision press shafts made?

Presses are a wide group of devices from the category of machines for plastic metal shaping, next to rolling mills or tractors. These are mechanical, eccentric, crank, hydraulic and specialized presses, designed to perform a narrow group of activities. They have different modes of operation, construction schemes and other methods of classification, and they always have one thing in common: precise parts of mechanisms. In our post, we will take a closer look at some elements of eccentric presses and the production of these parts.

Classification of eccentric presses

Eccentric presses can be classified according to various criteria, the basic of which is the division according to the shape of the body: overhang, frame. The second criterion is the option of changing the position of the slider and table - we have fixed and tilting presses. Another criterion is how to support the crankshaft. We distinguish presses with single-sided bearing shaft, double-sided bearing and single-sided bearing with additional crankpin support. Regardless of the construction, in each press the elements must be made very accurately so that the whole thing works smoothly.

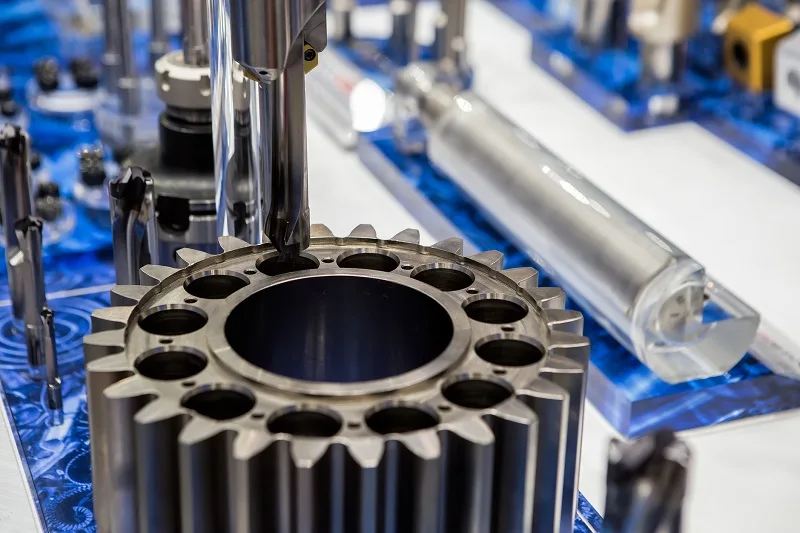

Machines producing machine parts. A few words about CNC machining

CNC machining, specifically computer control of advanced devices, allows us to create extremely precise elements - examples of details can be viewed in the gallery on our company's website. We rightly associate CNC machining with industry, which is with mass material production. This is right, and computer control of devices gives us the opportunity to produce elements on individual order. In the context of the press shafts we are discussing, we have some kind of loop here. We use machines to produce elements for subsequent machines, devices, tools, equipment, which are ultimately used again in production. The modern world of industry is increasingly advanced, extensive, using a lot of different techniques and technologies. It still gives a lot of jobs.